Filtration efficiency

The filtration efficiency of meltblown nonwoven fabric is determined by the size of the pores or fibers in the fabric. The smaller the pore size or fiber diameter, the higher the filtration efficiency.

Pressure drop

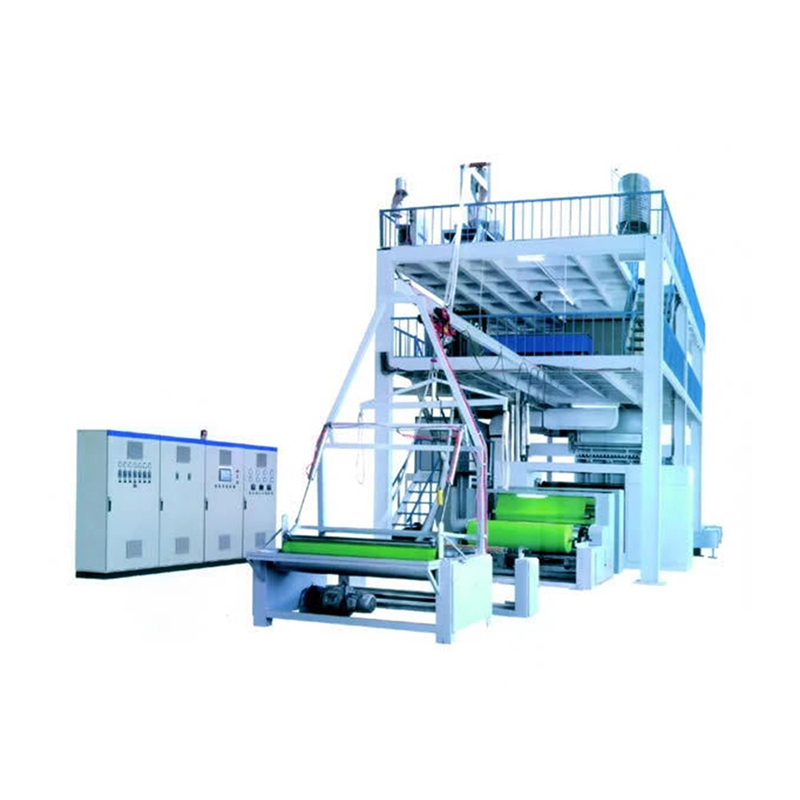

China meltblown nonwoven fabric machine produce meltblown nonwoven fabric to pressure drop, or resistance to airflow is an important property in filtration applications.Lower pressure drop means that the fabric allows air or fluid to pass through more easily, while higher pressure drop means that the fabric is more resistant to airflow.

Porosity

The porosity of the meltblown nonwoven fabric, or the percentage of open space in the fabric, is an important property for filtration applications. Higher porosity means that the fabric allows more air or fluid to pass through, while lower porosity means that the fabric is more dense and resistant to airflow.

Fiber diameter

The fiber diameter of the meltblown nonwoven fabric is an important property for filtration efficiency. Smaller fiber diameter means that the fabric can capture smaller particles, leading to higher filtration efficiency.

Surface area

The surface area of the meltblown nonwoven fabric is an important property for filtration efficiency. Higher surface area means that the fabric can capture more particles, leading to higher filtration efficiency.

These properties can be optimized through careful selection of raw materials, production parameters, and processing methods to meet the specific requirements of the filtration application.